Rapidform XOV Adds New Probe-Based Measurement and Speeds Up Inspection

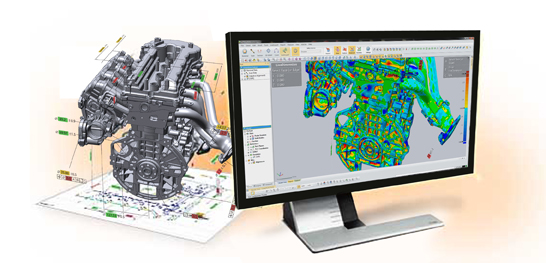

Seoul, South Korea - September 25, 2012 - Rapidform (www.rapidform.com), has announced the next major release of its CAD-intelligent inspection software, Rapidform XOV3. With this release, Rapidform XOV becomes a full-fledged contact inspection platform, with support for every major portable CMM device on the market. The completely new LiveInspect system, unique to Rapidform XOV, offers an automatic measurement guide that makes inspecting parts with a probe easy. After defining dimensions and tolerances on a nominal model, the software guides the operator how to measure a part and then generates a report automatically.

Seoul, South Korea - September 25, 2012 - Rapidform (www.rapidform.com), has announced the next major release of its CAD-intelligent inspection software, Rapidform XOV3. With this release, Rapidform XOV becomes a full-fledged contact inspection platform, with support for every major portable CMM device on the market. The completely new LiveInspect system, unique to Rapidform XOV, offers an automatic measurement guide that makes inspecting parts with a probe easy. After defining dimensions and tolerances on a nominal model, the software guides the operator how to measure a part and then generates a report automatically.In addition to the new probing capabilities of LiveInspect, Rapidform XOV3 has been extensively updated to offer near real-time inspection results. Calculations are up to 10x faster than before, making the process of aligning, deviation analysis and geometric dimensioning and tolerancing (GD&T) much faster and easier. In real world tests, the process of setting up inspection routines from dense point clouds takes less than half the time in this new release.

It also remains the most CAD friendly inspection software that can open native files from SolidWorks, PTC Creo (Pro/E), Siemens NX, CATIA V4/V5.

"We have significantly improved the user experience in Rapidform XOV3," noted Calvin Hur, CEO of INUS Technology. "We have optimized our existing calculation engine from top to bottom, making XOV a true pleasure to use. In addition, the new streamlined probing capability in LiveInspect has already been receiving rave reviews from our customers. Right down to the minor details, it is our mission to creatively innovate and unlock the power of 3D scanning for everyone."

New technologies in Rapidform XOV3 minimize errors, save time and make inspection more flexible, maintaining its reputation as the safer, easier inspection software. XOV is also the only native point cloud software with in-depth GD&T support for every callout in the ASME Y14.5 standard. With this new release, XOV offers several new features to improve productivity and accuracy in the inspection process.

Highlights of the 50+ enhancements include:

- LiveInspect, Rapidform's new probing interface for more streamlined, pain-free inspection processes

- Performance improvements resulting in huge times savings with calculations that are now up to 10x faster

- Real-time preview of scan pair geometry by simple mouse-over for instant verification

- Improved Reporting using customizable templates to share inspection results faster, more easily and automatically

Carl Singelais, Quality Engineering Specialist, is very excited about Rapidform XOV3. He remarked, "I got to see the beta version of the new XOV at CMSC in July. AWESOME! I can't wait to get it on my Arm. I love how intelligent and intuitive it is."

The latest version of XOV is available in English, German, Chinese, Korean, Italian, Russian and Polish.

For more information and to request a demonstration of the new features, visit www.rapidform.com/products/xov/xov3.

About Rapidform Rapidform products help companies unlock the power of 3D scanning. The company's software solutions are among the most widely installed products around the globe for reverse engineering, 3D imaging and inspection using 3D scan data. Rapidform makes 3D scanning an extremely powerful tool for a variety of applications and is used in fields such as manufacturing, R&D, quality inspection, medical research and civil engineering. Leading companies including Audi, Ford, Hyundai, Toyota, Rolls Royce, Volkswagen, Hitachi, Panasonic, Oakley, Samsung, Sony, Alcoa, and Bentley use Rapidform's advanced technology to innovate throughout their research, design, manufacturing and quality control processes. To experience the entire range of Rapidform 3D scan-to-CAD products and services, please visit www.rapidform.com.