Improving the design of a part within a system is rarely straightforward. From the simplest enhancement to the most complex, a cycle of iterations can be expected to verify the design during prototyping and implement it in production. During a recent test for a new valve product design, this experience played out for Philmac, a global leader in designing and manufacturing specialist fittings and valves for the transfer, control and application of water.

Accustomed to accelerating its design cycle with 3D printing for prototyping, Philmac expanded its use of 3D printing to prototype tooling in order to enable a more complex geometry. Teaming with 3D Systems On Demand Manufacturing experts in Australia, Philmac conducted a successful trial of this new methodology to bring its new concept to life.

3D Systems On Demand Manufacturing delivers the technologies, materials and expertise to support the entire product development lifecycle from fast turn and advanced prototypes to appearance models and low volume production.

Fast design validation

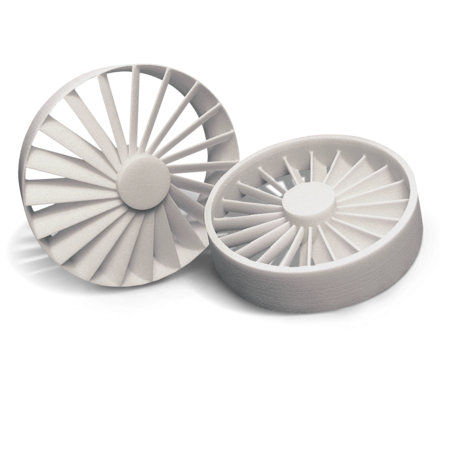

As one of Philmac’s new valve product designs was undergoing testing, an opportunity to improve its function in silty water applications was identified. Comprised of a body, piston, cap and spring, the valve design was revised accordingly and a prototype was 3D printed for testing. After refining the designs based on prototype test feedback, they were reprinted for another test cycle and confirmed.

Bringing the design revision into production meant two of the components would need a tool adjustment before samples could be manufactured. Whereas one of the tools could be adjusted by remaking a core, the other tool was far more complex and could not be achieved easily with the existing equipment. With a range of options available for component manufacture, Philmac had a decision to make. It could use aluminium prototype tooling, machine parts directly from Acetal rod, or seize the opportunity to trial a 3D printed tool. After discussions around cost and timing, Philmac decided to explore a 3D printing solution.

Partnering for the right solution

After contacting 3D Systems’ local Australian office, Philmac and 3D Systems met to discuss the solutions available. Though the project would be the first of its kind for each local office, the initial design review left both companies feeling confident about their choice in partner.

With 3D printed tooling design guidelines provided by an overseas sister company in the Aliaxis group, Philmac began researching desirable material properties to begin benchmark testing. In parallel, 3D Systems produced a series of material plaques for evaluation and provided Philmac’s team with background technical information to bolster its research.

Testing material properties

Philmac conducted comparative testing on the material plaques to determine the suitability of the various materials. Testing included heating the plaques to analyze material behavior at elevated temperatures, after which several plaques were ruled out. Following temperature testing, Philmac switched gears to measure pressure performance.

The four remaining plaques were subjected to compressive loads of 85kN and 100kN. Pressure performance results reduced the contending plaques to two. To determine the final material, Philmac repeated heat testing, this time heating each material to 180˚C, as the final selection would need to withstand the 220˚C melt-temperature of Acetal. On the basis of retaining both it shape and lettering, Philmac’s testing pointed to DuraForm® HST, a fiber-reinforced SLS material with high temperature resistance.

Philmac’s final evaluation involved comparing the properties of DuraForm HST with other 3D printing materials that had been identified in previous research on successful 3D printed production tools. 3D Systems provided additional plaques in DuraForm HST enabling Philmac to evaluate the material for machining and polishing suitability. Philmac was especially pleased with machining results.

Fully finished test parts on demand

Many of Philmac’s injection mould tools are family based and use change over cores and cavities. To test the 3D printed tooling, Philmac selected an existing tool that suited the 3D printed cavities based on the insert size required. For installation, the test team designed a steel ejector sleeve and nozzle inserts into the initial tool concept.

With its design finalized and material determined, Philmac placed an order for the cavity set with 3D Systems On Demand Manufacturing and received finished parts within the week.

From there, the inserts were machined to fit the ejector, nozzle and gate inserts and sized for fit into the tool.

Trial day and results

For the initial trial, Philmac loaded the tool to the injection machine to test the ejector function. Cooling circuits had been designed into the inserts, and air was connected to the tool for cooling, along with manual air directed onto the insert surfaces in between shots.

As part of Philmac’s testing precautions, the tooling team first applied mold release to assist with the release of the part. Beginning with 75% of the calculated weight and lower pressures for the initial shot, Philmac started the molding process and incrementally increased the shot and pressure until a full part was produced. At each stage, Philmac’s team checked the 3D printed blocks with an infrared thermometer to ensure recommended temperature ranges were reached at the surface and target before commencing the next cycle.

In the next phase, Philmac increased hold pressure to achieve a packed part. To mitigate the risk of material sticking to a thin rib on the core side of the tool, Philmac’s team reapplied mold release and hand polished the rib with sandpaper between shots to help keep the surface smooth. The settings were then increased until a stable part weight was achieved. According to Philmac’s tooling team, the 3D printed tool was a success and should be capable of making an additional 50 parts without incident.

Could 3D Systems’ experts and On Demand Manufacturing services help you succeed in your next project? Whether you need fast turn 3D printed parts, advanced prototyping with assembly and finishing services or low volume manufacturing including CNC, urethane casting and injection tooling, 3D Systems’ On Demand Manufacturing services can help.

Contact 3D Systems for more information on its complete On Demand Manufacturing services.