Piano-Forte factory Feurich was founded by Julius Gustav Feurich in 1851, making it one of the oldest piano manufacturers in the world. Feurich’s opus is an upright standing piano with bottom attenuation. This melodious object-de-art creates stunning acoustics, and has gained accolades both from virtuoso pianists and their audiences.

The modern day Mr. Feurich wanted to create a family of pianos from the masterful designs of his ancestors. He sought modern techniques to be certain he lost none of the old-world sound in the new models. Feurich contracted the services of Trimetric GmbH (www.trimetric.com) to unlock the secrets of the original handcrafted masterpieces.

Now pianos create acoustics, generated by the resonant frequency of the string and the sounding boards with which they interact, simple, right? If it were that simple, anyone could make a piano, and similar designs would have similar sounds, but the magic goes much deeper.

Feurich’s dilemma: How can one retain the soul of an old-world masterpiece when designing variations on the original, and employing more modern production methods. Trimetric answer: 3D scanning technology enables the faithful capture of the shapes including the artifacts of handcrafting. Geomagic Design X uses that scan data to describe the original designer’s intent as well as capture and superimpose those hand-working artifacts. The resulting CAD models become the basis for manufacturing new piano parts from modern processes.

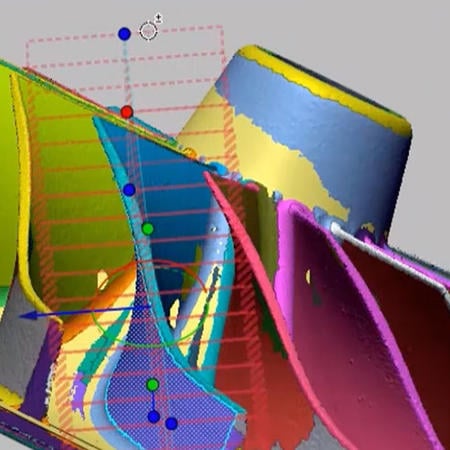

A parametric CAD model from 3D scan data, is necessary to meet customers’ requirements, faithfully capturing, both the design intention of Julius Gustav Feurich, as embodied in each component that he made. Geomagic Design X is a unique program, CAD models are designed in the context of 3D scan data. The scan data serves as a template from which each parametric feature is derived. As each arc, cylinder and fillet is created and combined in Design X, the Accuracy Analyser(TM) allows the designer to check the shape of resultant model data relative to the scan data on which it is based. An observant user knows immediately if they have created a feature that deviates from the scan, and can correct it before other errors result. The resulting shapes and the steps to create the model are recorded and then exported – in sequence — into the CAD system. Each command is re-executed by the recipient CAD system resulting in a native editable parametric CAD model.

Dipl.-Des. Bernd Würdemann from Trimetric GmbH (www.trimetric.de), has been in charge of this project, he is very satisfied with the modeling results and he remarked, “To redesign the original hand-made shape of the wing frame of the piano was big pleasure and I am proud of the results, thanks to Geomagic Design X”. Because of Design X’s key features; parametric CAD Modeling in the context if the scan data, you can save most of time that modeling would take using other tools. Further, Design X offers a seamless integration with popular PLM solutions like SolidWorks, Pro/Engineer and Siemens NX. The operator can easily modify any feature of the model in the history tree in your CAD software or in Design X, and one can see that change propagate to associated (children) features.

What was the result? Mr. Feurich was happy with the project, saying that, “Through the innovative technology of 3D Scanning, I am convinced more about the future and will keep contributing my arts to the new world of Music. Even though my skills are more than 100 years old, I see that it will be preserved and delivered to next generation with better achievement over several centuries. Once again thank you for the technology created by 3D Systems!”