When a cell phone subsupplier for Ericsson, Nokia, and Siemens requested an inspection of a CAD model within 15 minutes, Cascade Computing of Sweden didn't sweat it. With Geomagic Control (formerly Geomagic Qualify) rapid inspection software from 3D Systems, it was a simple job.

Cascade, a computer solutions company serving Scandinavia, was asked to inspect the part for three known errors as part of a simulated performance benchmark. With Geomagic Control, Cascade quickly found the three errors, as well as other errors the makers weren't aware existed.

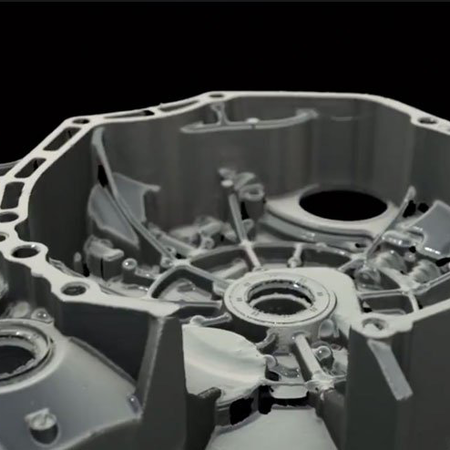

Geomagic Control allows automatic graphical comparisons between a CAD master model and the built part or object. Shop-floor inspectors, technicians, and design engineers can use Geomagic Control to quickly and easily overlay, evaluate and report deviations between designed and built parts. Inspections can be performed with one click of the mouse and results shared with colleagues via automatically generated, web-ready HTML reports. Geomagic Control provides accurate comparisons that allow users to comply with even the strictest deviation standards.

Cascade started the benchmark by digitizing a cell phone part with an ATOS HR SO scanner, which captured 500,000 points in 10 minutes. Geomagic Control enabled the company to compare models based on a specified level of tolerance of 0.003 mm. Within five minutes, the software displayed deviation results using color-coded representations that are easy to decipher. Geomagic Control also automatically generated a green and red "go/no-go" display.

Cascade also uses Geomagic Studio for rapid reverse engineering. The company provides a wide range of services, including CAD/CAM, reverse engineering, modification and repair, milling, verification, and rapid inspection.