Less than a year before this story was written, Carlos Roberto Sales could barely eat or sleep. He didn’t want to work or even leave his house. His beard hid a terrible wound on the left side of his face from an accident and a subsequent bone infection from a botched surgery. He felt as if he had lost his identity.

"The face of a man is his identity," says the 47-year-old Brazilian real-estate agent. "When a man loses his face, he has lost much more than his appearance."

Today, Sales is a new man. After reaching his low point, he contacted Dr. Frederico Salles and Dr. Marcos Anchieta, who were working with Dr. Cesar Oleskovicz on new bone implant technology. For Dr. Oleskovicz and his fellow surgeons at the Center for Maxillofacial Rehabilitation ORIS (Brasilia, Brazil), 3D virtual prototyping is turning tedious and time-consuming surgery into a more precise and expedient way to treat patients with maxillofacial disorders.

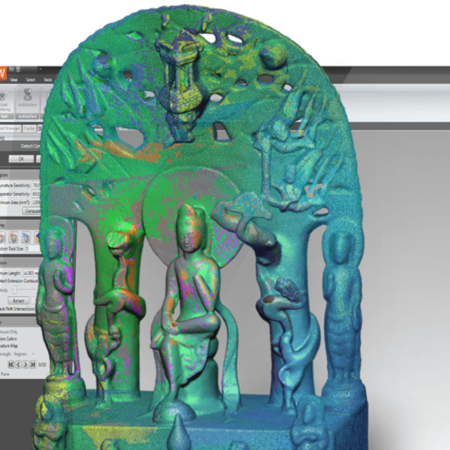

Dr. Oleskovicz uses the latest medical CAD programs, 3D graphics software, and Geomagic Studio to create custom maxillofacial implants for patients with bone defects or diseases of the face.

These are the technologies that enabled surgeons to change Sales’ life. "I now have normal mouth movements and I can eat normally again. I recovered the trust in myself, without the fear of people looking at my face," he says.

A Highly Specialized Field

Oral and maxillofacial surgery is a highly specialized form of dentistry. It includes the diagnosis, surgical and adjunctive treatment of disease, injuries and defects involving the mouth and maxillofacial region. These surgeons deal with issues ranging from facial injuries and cancer, to congenital bone defects.

Because many facial surgeries involve reconstruction, they require careful planning and intricate techniques to achieve a patient’s desired result. Unlike other bone injuries or disorders, doctors cannot fix the problem with a simple cast.

Advanced CT scanning and MRIs can now create 3D images of the facial area for a precise diagnosis. And rapid prototyping – stereolithography, selective laser sintering, or fused deposition material – can be used to both plan and build a precise implant to replace damaged or diseased bone.

While advanced scanning, CAD and rapid prototyping technologies opened new doors for Dr. Oleskovicz, they didn’t solve one of his biggest problems, which cropped up again in a recent surgery. A woman had a very large tumor in her lower jaw, and Dr. Oleskovicz had to construct a steel implant to replace bone that would be removed with the tumor.

"This project was very simple in its objective, but complex in its realization. I had to replace the total right side, the total chin, and 80 percent of the left side," he says. "The tumor was so large, the program that does the conversion from the CT scans to the mathematical models was creating files that were too big and complex to manipulate in any CAD program. I needed a workable 3D object without precision loss."

In the past, because the files were too big to export into the CAD program, Dr. Oleskovicz was forced to start the implant process in the CAD program and then work backwards, testing its fit in a 3D mathematical model program. This led to a long process of trial and error in which he had to keep returning to the CAD program to adjust the fit and then test it again in the mathematical model.

"I went through these steps hundreds of times. It was a terrible amount of work," he says.

Implanting New Concepts

Realizing that he would continue to have this problem, Dr. Oleskovicz searched the Internet and found Geomagic Wrap, an ideal tool for optimizing polygonal data for 3D virtual prototyping applications.

Geomagic Wrap allows for instant and automatic polygon reduction of any surface, regardless of complexity. The reduced file size dramatically improves rendering speed, while preserving the surface geometry of the object.

"Geomagic played an important role in this woman’s surgery by allowing me to work with these giant mathematical files without precision loss," says Dr. Oleskovicz. "It is easy with Geomagic Wrap to manipulate even the largest STL files [for stereolithography]," he says.

Dr. Oleskovicz used Geomagic Wrap after converting the CT scans to mathematical data in a 3D computer graphics program specifically designed for medical imaging. "Geomagic saved so much time that it would have been nearly impossible to complete the implant planning process without it," he says. "If I was importing the 3D mathematical models without Geomagic Wrap, each time I would need hours for adjustments."

From Virtual to Reality

After the implant process was tested with 3D computer models, the patient’s implant was brought to reality through rapid prototyping. With the accuracy of Geomagic Wrap, Dr. Oleskovicz’s patient now has a perfectly sized new jaw.

This latest patient was the second of many who will receive maxillofacial implants with the aid of Geomagic Wrap at the Center for Maxillofacial Rehabilitation. Dr. Oleskovicz plans to continue using Geomagic for his surgeries, particularly his next one, which will use a newer material for the implant.

"My studies don’t stop here," he says. "The next implant will be made of polymer material instead of metal. Because the polymer is lighter than metal, the correct anatomy of the patient’s bone can be replicated. I will therefore need more computer graphics knowledge to get the perfect 3D file for the bone surface."

For the patient, these newer computer techniques make the end result worth the trial of the treatment.

"This type of surgery can be very hard on a patient," says Dr. Oleskovicz. "It is our job to deliver an implant that has perfect biocompatibility, functions like real bone, and is aesthetically pleasing. Computer technology like Geomagic Wrap makes that process easier."

For Carlos Roberto Sales, it has meant a new lease on life. "My main pleasure is to wake up in the morning, shave my beard, look at myself in the mirror and go to work," he says. "I lost my identity, but now I have it back."