Issue No. 3 – “What Can I Make With This?” - 3D Printing’s Biggest Question, Part I – Consumer Printing and Plastics

By Joe Borrello, Project Lead at DynamiCal: in situ Imaging Solutions

This is an ongoing series that looks at 3D printing from more than just a technical perspective. While technical metrics often inspire much of the interest and focus of new technologies (and are indeed an important part of them), zeroing in on such data can cause us to miss the forest for the trees in terms of how 3D printing will impact society and life. To get a more balanced perspective regarding what this technology means to us as individuals and as local and global communities, we must adapt the right printing philosophy – or “printlosophy” – which is what this series attempts to do.

If you’re a stickler for title-reading, you’ll notice my job has shifted and I am no longer working at 3D Systems. I’ve always been simultaneously involved in the tech startup world and one of those ventures has recently advanced to a new stage requiring my full-time attention. That being the case, 3D printing is still a major part of my life and I am no less passionate for the tech than I was while working at 3D Systems. In fact, it should come as no surprise that 3D printing is playing an integral role in the prototyping and product development operations of my new startup. But enough about me! Let’s get on with today’s topic.

This issue will take a preliminary look at one of the biggest questions surrounding 3D printing right now: “What can I make with one of these?” This question is often packaged in different ways, including:

- “You can print toys for your kids on this, right?”

- “Can you print a gun on that?”

- “They just printed a car on one of these?”

- “Do you print organs?”

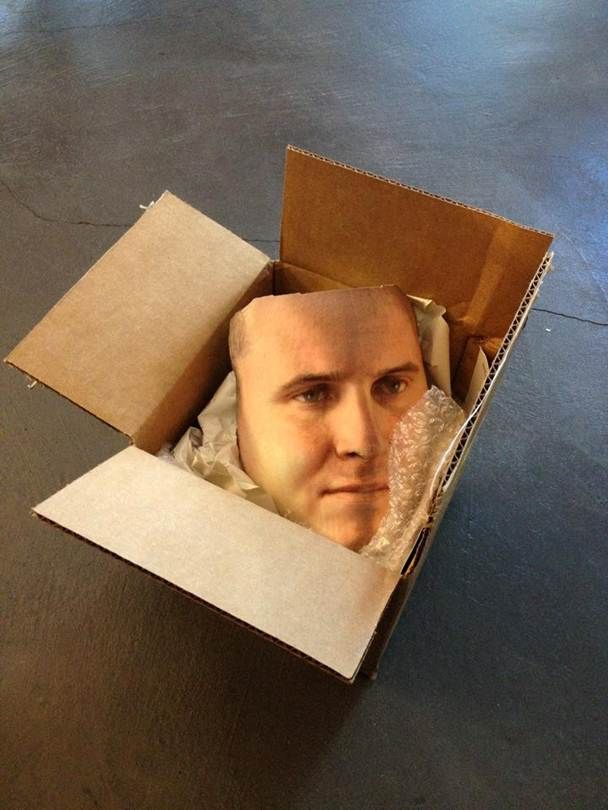

- "Can you print in multiple colors?" (Photorealistic color, as the picture proves)

The answer to all of these questions is yes… and no. “3D Printing” is a term that casts a wide shadow over a great many technologies, which are (paradoxically) all fundamentally unique and all fundamentally the same. Yes, we can 3D print in living tissue as well as in metal, plastic, and wax, but not all printers can print in all materials. In fact, many 3D printers can only print in one material, though in some cases a handful of unique materials share similar chemical properties that make multiple materials possible. In each case, the 3D printer is building models layer-by-layer, but how those layers connect to one another can vary tremendously based on the material used.

My first printlosophy dealt with PJP/FDM/FFF printers that work like high-tech hot glue guns. These printers comprise the vast majority of the consumer market and can probably print in the widest array of materials. This wide material palette is afforded by the magic of plastics and our ability to mix just about any other material into them. This means that for the fundamental thermoset plastics – PLA, ABS, Nylon, Polycarbonate – there are dozens of “seasoned” combinations that can be produced with materials like copper dust, wood pulp and carbon fiber. These mixed-in materials give the plastics different appearances (and sometimes smells) but do not ultimately change their printing properties to a significant degree.

Other printing is less amenable to material swapping. Printing methods that use resins and UV light – SLA, Multi-Jet Printing and PolyJet Printing – all use chemical derivatives of acrylic polymers that solidify with exposure to UV light. Each successive layer of resin bonds to the previous once the UV lamp or laser of the printer hardens it. SLS and Direct Metal printing work similarly, except instead of a chemical reaction initiated by UV light, a high-powered laser fuses layers together by melting powders just enough for them to melt into one another. For these cases, printers are calibrated, and in some cases even designed, to only work with a small portfolio of materials, all of which react the same way to the printing process. You can’t manipulate the power of a laser in the same way you can change the temperature of your extruder on a consumer 3D printer.

This long-winded introduction to the topic brings me to the general answer to all of the questions listed above: “Don’t expect to print your kidneys, iPads, cars or any other advanced technology on your 3D printer any time soon.” The technology simply isn’t there yet for use in the home, and in some cases, such as with metal printing, it may never be safe outside of well controlled, industrial settings.

So am I saying you can only print stuff out of plastic? Mostly yes. Don’t get me wrong: there are tons of composite designs and applications you can find with multi-extruder PJP/FDM/FFF printers and there are people out there doing some incredible things with them, but for the most part we’re looking at a one-plastic-at-a-time process; at best, two or three different types at a time.

For many people, this has been a major turn-off for 3D printing. Everyone figures all they could make on their own printer would be plastic tchotchkes, but I bet you use more plastic tchotchkes than you realize. As The Graduate famously predicted, the future is founded in “plastics”. This was true before 3D printing ever existed, and it will probably continue to be true should 3D printing ever be replaced with something else. The only label that might be more all-encompassing than “3D Printing” is “plastic”. Essentially, plastics are polymers (long chains of molecules), which, as it so happens, is what pretty much everything is made of. As of now, 3D printing hasn’t really shown us how to make new things out of plastic; it’s shown us how to make the things we already own in plastic in exciting new ways. Cool though it may be, plastic is plastic (is plastic).

I promise I’m not trashing the industry though. I find great value in the plastic belongings I own through traditional manufacturing. The way I see it, the advantage of 3D printing is that I can make these items work for me better than they already do, whether through customization or on-demand production. For me, it’s gotten to a point where I can walk into stores like Bed, Bath & Beyond or Home Depot and find at least 5 items for sale that I could print at home to my own specifications, with equal or higher functionality.

Home 3D printing won’t replace these stores, nor will it replace the electronic shops and car dealerships of the world. However, it can fill certain needs and wants very well as long as you know how to think about it.

For this reason, I propose a 7-day challenge to all readers of this blog and those generally interested in 3D printing. Every day for one week, find an object or desired object in your life that could be made with 3D printing. Don’t worry about how it would get made or where it can be found, just think about the object. As long as you keep 3D printing in mind, you should have no trouble thinking of 7 items you could print. In fact, you may find that you start seeing printable objects everywhere.