Bastech combines Cimatron software, Direct Metal Printing (DMP) and Geomagic Control to deliver complex conformal cooling channels in advanced mold-making applications 3D Systems and Bastech to host webinar sharing best practices for efficient and economical conformal cooling design and production

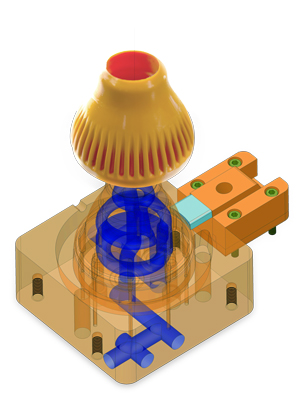

ROCK HILL, South Carolina, June 14, 2016 – 3D Systems (NYSE:DDD) announced today that Bastech, a partner and one-source solution provider for additive manufacturing services and equipment, used 3D Systems' end-to-end 3D solutions to introduce a new level of simplicity, efficiency and economy to its conformal cooling mold-making process. By combining the tailored mold design toolsets of Cimatron™ with the flexibility of the ProX® DMP 200 for producing complex metal geometries and Geomagic® Control™ for quality inspection, Bastech was able to reduce design time by 70%, cycle time by 14% and overall costs by 16%. In the manufacturing industry where success is a delicate balance of efficiency, cost and quality, these benefits give Bastech a clear competitive advantage.

Watch this video showcasing the many ways Bastech is using 3D Systems' software and 3D printing solutions to improve its design and manufacturing process.

For over two decades, Bastech has used additive manufacturing technology to solve a wide range of applications, from functional prototypes for the automotive industry to complex investment casting patterns for end-use aerospace components. Well versed in traditional as well as additive methods, Bastech recently performed two benchmark tests for manufacturing molds with conformal cooling channels – one using 3D Systems' end-to-end solutions, and one using conventional processes. The Ohio-based firm found that using 3D Systems' Cimatron mold-making software, the ProX DMP 200 3D printer and Geomagic Control led to a quantifiably more productive, affordable and streamlined manufacturing process.

Together with 3D printing on the ProX DMP 200 and quality inspection via Geomagic Control, Cimatron design and analysis saved the firm more than 40 hours of programming and shop time compared with traditional methods, amounting to valuable savings for the firm. More importantly, the effectiveness of the conformal cooling mold that Bastech produced led to a more efficient production run, boosting company productivity even further.

"The bottom line is that by working with Cimatron, Direct Metal Printing and Geomagic Control, we are designing faster and making more efficient molds more economically," said Ben Staub, President and Owner, Bastech. "3D Systems' end-to-end solutions take our business to the next level by saving our designers and engineers time and energy in developing and executing complex designs."

"Combining our advanced technologies allows our customers to achieve better and more innovative outcomes," said David Lindemann, Applications Engineer, 3D Systems. "End-to-end digital workflows are transforming the field of manufacturing."

3D Systems will host a design and manufacturing webinar with Bastech on June 16th to share findings from Bastech's benchmark testing and talk about best practices in conformal cooling. During this hour long webinar, Bastech president and owner Ben Staub and Bastech engineering manager Scott Young will discuss how 3D Systems' end-to-end solutions can lead to greater efficiency and reduced costs.

The webinar will take place on June 16, 2016, at 11 AM EST. Pre-registration is required.

To learn more about Bastech, please visit www.bastech.com

About 3D Systems

3D Systems provides comprehensive 3D products and services, including 3D printers, print materials, on-demand manufacturing services and digital design tools. Its ecosystem supports advanced applications from the product design shop to the factory floor to the operating room. 3D Systems' precision healthcare capabilities include simulation, Virtual Surgical Planning, and printing of medical and dental devices as well as patient-specific surgical instruments. As the originator of 3D printing and a shaper of future 3D solutions, 3D Systems has spent its 30 year history enabling professionals and companies to optimize their designs, transform their workflows, bring innovative products to market and drive new business models.

More information on the company is available at www.3dsystems.com